As pilots we cannot control every variable that goes into a safe, successful flight. We have to assume some risk. We have to, for example, assume the aircraft was designed properly. We have to assume our mechanics knew what they were doing the last time they worked on our aircraft. In an airline the assumptions go even farther. With some airlines, you leave the de-ice/anti-ice up to the ground crew and you have to assume they did a good job. Sometimes these assumptions are wrong. I wrote about that for Business & Commercial Aviation Magazine here: Assumed Safety (October 2016).

— James Albright

Updated:

2020-19-08

Damage to aircraft,

SHK Accident Report, p. 17

These pilots were presented with a situation they were ill-prepared to deal with. You should never be content to learn only what the company (airline, simulator vendor, etc.) wants to teach you. These pilots could have been better armed with a little extra knowledge. As it was, they found themselves flying a very large glider; but they did a very good job salvaging a bad situation.

1

Accident report

- Date: 27 December 1991

- Time: 0851

- Type: McDonnell Douglas DC-9-81 (MD-81)

- Operator: Scandinavian Airlines System (SAS)

- Registration: OY-KHO

- Fatalities: 0 of 7 crew, 0 of 122 passengers

- Aircraft fate: Damaged beyond repair

- Phase: Climb

- Airport (departure): Stockholm-Arlanda Airport (ESSA), Sweden

- Airport (arrival): København-Kastrup Airport (EKCH), Denmark

2

Narrative

In an airline you should have ground crew trained to determine if the aircraft is free of ice and pilots are more at less at the mercy of the ground crew. The same applies in the U.S. of commercial crews who have been trained under the provisions of 14 CFR 121.629(c) and 135.227(b). But all pilots should be wary of the effects of cold fuel in wet wings in conditions conducive to frost or icing, or even in conditions of high humidity. In these conditions, a de-ice treatment may not be good enough. You should consider an application of anti-icing as well as a pre-takeoff contamination check.

A noteworthy element to this accident was the presence of a third pilot in the cockpit to provide a calming influence and a third set of eyes to avoid mistakes. This off-duty pilot kept the PF focused on getting the airplane safely on the ground, remembered to get the flaps, and provided assurance that the gear should be extended for the crash landing.

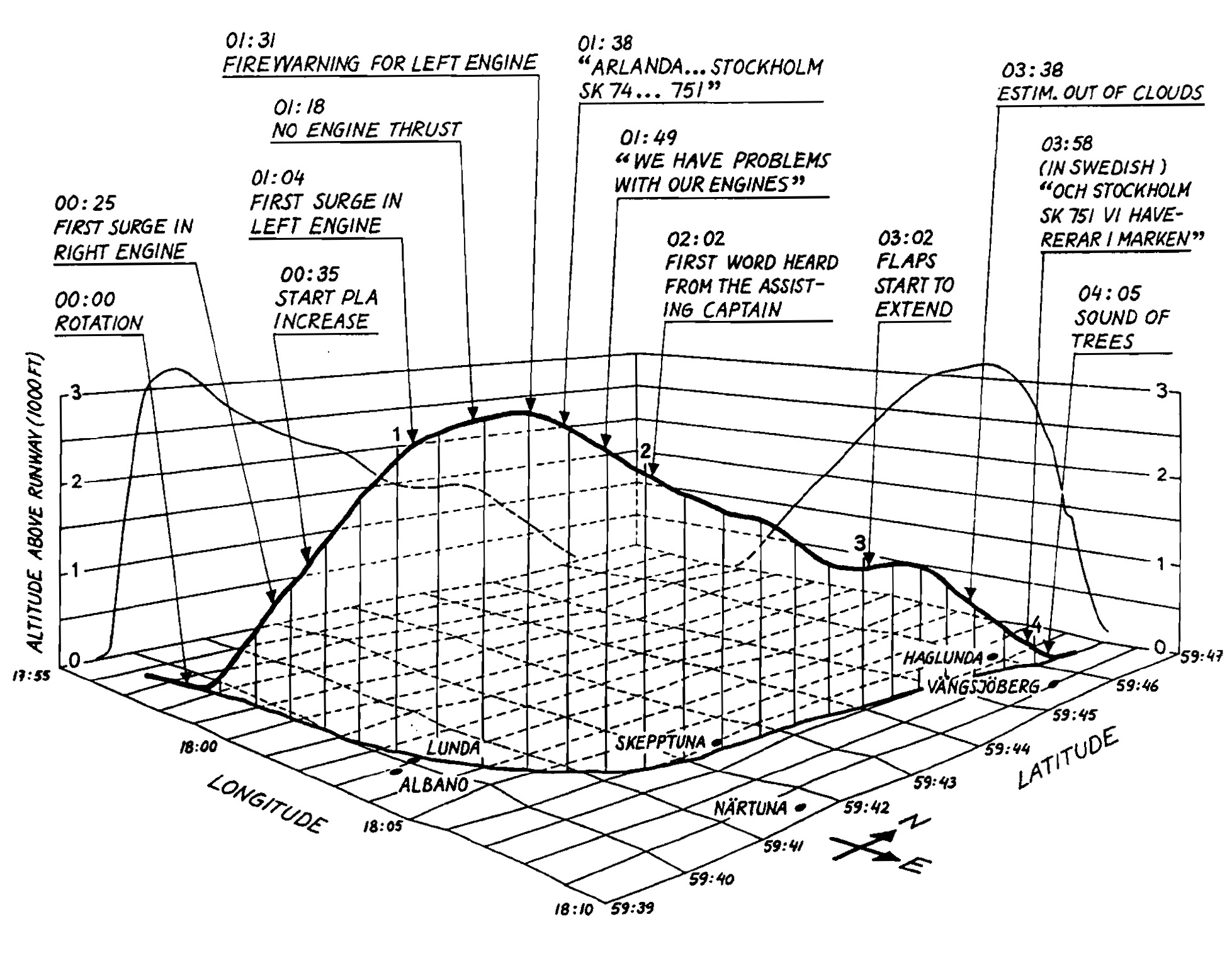

Flight path, SHK Statens haverikommission Accident Report, p. 15.

Weather. METAR Stockholm/Arlanda 0850 hrs: Wind 360° /11 kts, visibility > 10 km, light intermittent snowfall, cloud 2/8 stratus base 600 ft, 6/8 stratus base 800 ft, temp/dewpoint -0°C/-1 °C, QNH 1013 hPa, Sunrise 0848 hrs

Source: SHK Statens haverikommission Accident Report, p. 9

- An aircraft of type DC-9-81 operated by Scandinavian Airlines System (SAS) and registered in Denmark with the markings OY-KHO landed at Stockholm/Arlanda Airport on 26 December, 1991, at 2209 hrs. It came from Zurich and had been flown at cruising altitudes at which the external air temperature varied between -53 and -62°C. The flight at these altitudes had lasted approx. 1 hour and 40 minutes. On landing there remained approx. 2,550 kg fuel in each wing tank.

- After landing the aircraft was parked at gate 2 at the international terminal. During the night a flight technician inspected the aircraft. He was compelled to clean slush from the landing gear to be able to inspect it. When he left the aircraft on 27 December at approx. 0200 hrs he noted that ice had formed on the upper surface of the wings. The air temperature had up to that point been + 1 °C.

- On the morning of 27 December the aircraft was to be flown to Copenhagen on SAS flight SK 751 with scheduled departure at 0830 hrs. The mechanic responsible for handing over the aircraft on the morning of 27 December noted at about 0730 hrs frost coverage on the underside of the wings. He therefore checked whether there was ice on the upper side of the left wing by climbing a ladder, putting one knee on the wing and feeling the forward part of the wing with his hand. He found no ice, but did find slush. Using a ladder he checked the air inlet of the left engine and found nothing abnormal. At 0650 the external air temperature had sunk to +0°C. At 0820 hrs an external air temperature of -0 ° C was recorded.

- The aircraft was fueled with 1,400 kg of fuel and was ready for de-icing at 0830 hrs. The mechanic had after consultation with the captain ordered de-icing of the underside of the wings also, because of the frost they had seen there. There had been no discussion of clear ice.

- During de-icing of the upper side of the wings the mechanic after a first spraying with de-icing fluid ordered further de-icing to make sure that the wings would be free of slush. For the de-icing a total of 850 I de-icing fluid type I was used. The temperature of the fluid was approx. 85°C. After de-icing the mechanic did not check whether there was any clear ice on the upper side of the wings, since he had previously found none.

- The person who operated the spray nozzle of the de-icing truck has stated that he saw that one of the four indication tufts fixed to the upper side of each wing moved during the spraying. A passenger who had been sitting in a window seat reported that the tufts on the wing he could see through the window did not move during the spraying.

Source: SHK Statens haverikommission Accident Report, ¶1.1

In a classic sense, a "tuft" is a piece of string attached to the aircraft at one end and loose at the other to show relative airflow. In the meantime, you can see one here: https://lessonslearned.faa.gov/ll_main.cfm?TabID=3&LLID=29&LLTypeID=2#null.

- The mechanic reported to the captain "Yes, de-icing finished". During the engine startup procedure the captain asked "And they've got it good and clean under the wings?" The answer was "Yes, there was a lot of ice and snow, now it's fine. it's perfect now". This part of the conversation between the captain and the mechanic ended with the captain saying: "That sounds fine, then, thanks".

- While the aircraft was being de-iced the pilots carried out a routine run-through of, among other things, the departure procedure from Stockholm/Arlanda. During this the captain mentioned, regarding the procedure for engine failure "Engine failure follow ... 2000 ... that's very general".

- After engine startup the captain taxied the aircraft to runway 08. The engine de-icing systems were 'on' for both engines and there was no indication of malfunction in the systems. While taxiing out the captain initially steered the aircraft somewhat to the side of a strip of slush, which was finally crossed at low speed. The average speed during the taxiing, which took approx. two and a half minutes, was 15 kts (28 kph). The captain made a rolling take-off which up until the rotation went normally. The Auto Throttle System (ATS) was engaged.

- The captain started to rotate the aircraft at 0847.07 hrs. Three passengers have said that they saw ice coming off the upper side of the wings as the aircraft took off. At the same time the captain heard an abnormal noise which he could not identify. The sound was recorded by the Cockpit Voice Recorder (CVR) as a low hum.

- After about 25 seconds, flight bangs, vibrations and jerks were perceived in the aircraft. The jerks were experienced as repeated heavy braking.

- The pilots realised that engine malfunctions had developed and, using the engine instruments, traced the malfunctions to the right engine. The first officer said " ... think it's a compressor stall". The captain has stated that - because of the vibrations and the rapid changes in the digital presentation - he had difficulty in reading the engine instruments. He reduced right throttle somewhat, but without the malfunction ceasing. The throttling-down was recorded as a reduction from 1.904 EPR to 1.870 EPR. Altitude was then approx. 2,000 ft (600 m) and 43 seconds had passed since commencement of rotation.

- It can be seen from the aircraft's flight recorder that engine surges had occurred. In the right engine the first surge was recorded 25 seconds after rotation. The aircraft was then at 1,124 ft (343 m) and in cloud. The autopilot was not switched on. According to the flight recorders, throttle control simultaneously changed to an automatic mode which increased throttle setting with altitude. This was indicated discreetly on the instrument panel but not noticed by the pilots.

- In the left engine the first surge was recorded 64 seconds after rotation. The pilots never realised that the left engine was surging.

- An attempt to switch on the autopilot at an altitude of 2,616 ft (797 m) failed and activated the voice warning "Autopilot". The warning continued for the rest of the flight.

- The right engine failed 51 seconds after the first engine surge had been recorded. The left engine failed two seconds later, 78 seconds after rotation. The aircraft's indicated speed was then 196 kts (363 kph) and indicated altitude 3,206 ft (977 m). Shortly after this the aircraft reached its greatest indicated altitude 3,318 ft (1,011 m).

- Slightly later the two EFIS display screens in front of the captain went dead. He made no attempt to recover the EFIS presentation so during the rest of the flight had to rely on a smaller backup instrument for his flight attitude information.

- The first officer has stated that it was only when the engines stopped that he noted the warning indications from the engine instruments and saw that the outlet temperatures were over 800°C. Thirteen seconds after all thrust had ceased, fire warning was given for the left engine. The first officer then activated the fire extinguishing system for that engine. Grey smoke was noticed in the forward part of the aircraft. Fire warning ceased after 26 seconds.

- The air hostess sitting in the cabin rear jump seat was informed by a flight captain traveling privately that the right engine was surging. She tried unsuccessfully to contact the aircraft's captain on the intercom to notify him. She then got the message to the purser who passed it on to the captain.

- A uniformed SAS captain in seat 2C realised that the crew were having problems. He hurried to the cockpit and asked if he could be of any help. The first officer gave him the emergency/malfunction checklist and the captain instructed him to start the auxiliary power unit (APU). The assisting captain's voice was first recorded two minutes and two seconds after rotation when he said "Look straight ahead". He then urged the captain several times to "look straight ahead".

- Once the engines had lost all thrust the crew prepared for emergency landing. The captain began to glide the aircraft in a gentle left turn which was interrupted on an approximately northerly heading. At the same time the first officer notified Stockholm control that there were engine problems and asked to return to Stockholm/ Arlanda. The air traffic controller ordered a right tum to bring the aircraft back for landing at Stockholm/Arlanda (runway 01). The captain continued, however, the northerly glide. The captain called several times "Prepare for On Ground Emergency". The order was passed aft once by the assisting captain. The purser made a complete announcement over the PA system in accordance with the notification.

- When the aircraft was approx. 420 m above the ground and still in cloud the assisting captain started gradually extending the flaps. According to the flight recorders, speed was then approx. 165 kts. The flaps were fully extended approx. 30 seconds later at a height of approx. 300 m above the ground. At a height of approx 340 m (1,100 ft) above the ground the captain said: "Flaps eh ... eh", whereupon the assisting captain answered: "Yes, we have flaps, we have flaps, look straight ahead, look straight ahead!"

- When the aircraft was entirely free of the cloud at 300 to 250 m (980 to 820 ft), the captain judged that a large field far to the right could not be reached. Instead he chose to attempt an emergency landing in a field more or less in his direction of flight, north-east of Stockholm/Arlanda. During the approach to the field the captain corrected his heading about 25 ° to the right to avoid houses further on in the intended direction of landing.

- Seventeen seconds before the aircraft struck the ground the first officer asked "Shall we get the wheels down?" This was answered by the assisting captain with the call: "Yes, gear down, gear down." Eight seconds later, when height was 56 m, the first officer reported to Stockholm control: "and Stockholm SK 751 we are crashing to the ground now." A further seven seconds later the sound of contact with trees was recorded on the CVR.

- According to the flight recorders the landing gear was extended and locked at about the same time as the aircraft hit the first trees. The speed had then decreased to 121 kts. The major part of the right wing was torn off and the aircraft began to bank right. The last flight recording one second before impact was 107 kts, with a 19.7 ° right bank.

- Four minutes and seven seconds after rotation the aircraft hit sloping ground, first with the tail. On impact, a right bank of 40.1 ° was recorded. After impact the aircraft slid along the ground about 110 m before stopping. The fuselage was broken into three on impact and during the subsequent braking along the ground. There was no fire. All 129 on board survived. Except for four persons, all made their way out of the aircraft themselves.

Source: SHK Statens haverikommission Accident Report, ¶1.1

3

Analysis

Dealing with a compressor stall used to be a mandatory part of any jet pilot's training, but jet engines are made so much better that this training has gone away. If you ever feel the engine compressor stall (large "bang," vibration, loss of thrust and an increase in EGT, TGT, or ITT), the corrective action is to retard thrust until it recovers. You need to verify the engine speed has decreased in response to power lever movement.

Aircraft wreckage, SHK Statens haverikommission Accident Report, p. 35

- Aerodynamic disturbances in a compressor in operation can lead to engine surging. This occurs at high power setting when the compressor is no longer able to compress the incoming air to the pressure obtaining in the engine's combustion section. The air flow then suddenly reverses, is shot violently in the opposite direction and a surge occurs. In favourable conditions the engine normally recovers directly the pressure in the compressor and combustion section sinks. But if the original aerodynamic disturbances persist, a new surge can rapidly develop. Normally, repeated surges cease if the power setting is reduced sufficiently.

- Engine surging entails very great thermal and mechanical strains, which can cause damage to the engine. Special inspection is normally required when an engine has surged.

- The surge margin is a way of expressing the engine's resistance to aerodynamic disturbances. Greater margins give better conditions for the engine to absorb external and internal aerodynamic disturbances without developing surging. The surge margin varies between engine types and individual engines. Damage or wear to fan blades, compressor blades or guide vanes and much clearance between blades and external seals are factors that can cause aerodynamic disturbances in a compressor. The disturbances can alter the relationship between the rotors' rotation speeds, which can reduce the surge margin.

- A comparison between the engine type in the MD-81 and other available engine types of the same category including the DC-9 type, shows that new engines of these types have approximately the same surge margins.

Source: SHK Statens haverikommission Accident Report, ¶1.6.3.3

- Certain airlines, but not SAS, employ noise abatement thrust cutback procedures. When these procedures were approved, the FAA made certain views known. These led to the type being equipped with a system that in a case of engine failure automatically increased the thrust of the other engine. The system, which functions independently of ARTS [Automatic Reserve Thrust System], was certified in March 1983 and subsequently introduced as standard irrespective of whether the special takeoff procedure was used. Not until 1992 was the designation Automatic Thrust Restoration (ATR) introduced in the FAA Approved Airplane Flight Manual and in the MDC Flight Crew Operating Manual. The present report uses the term ATR even though this term had not been introduced at the time of the accident.

- When the ATR is activated the CLAMP function ceases, ATS is reactivated and the thrust level automatically changes to G/A, which corresponds to an "active" and normally higher EPR (increases on increased speed and altitude). If ATS is switched on and EPR for G/A is higher than EPR for TO, the engine throttle levers are automatically moved forwards until the thrust of one engine reaches EPR for G/A.

Source: SHK Statens haverikommission Accident Report, ¶1.6.4.5

- Since the aircraft was vibrating heavily and the engine parameters were fluctuating rapidly, the engine instruments were difficult to read, particularly for the captain who also had to concentrate on flying the aircraft. In these conditions the pilots found the digital presentation, in particular, hard to read.

- Despite the difficulty of reading the instruments the pilots traced the malfunction to the right engine and the first officer suspected surging. At this point the captain moved the right engine throttle lever backwards without the surging stopping. This was recorded by the QAR as a throttle lever change by about 10%. Since ATR had been activated previously, however, the throttle lever had moved forwards about 7% from the CLAMP position. Therefore the captain's action moved the throttle lever backwards to a position that was only 3% lower than the CLAMP position. If the corresponding reduction had been made from the CLAMP position, the power would have been reduced by another 7%. Whether this would have been enough to eliminate the engine surging cannot be established. Since ATR was in operation, which the pilots were unaware of, the throttle increase continued as soon as the captain had released the throttle lever.

- Engine surges are not unusual in modern jet engines. They can lead rapidly to the engine's destruction. It is therefore of the greatest importance that the pilots without delay take the action to stop the surges prescribed in the emergency/malfunction checklist. The Board of Accident Investigation find it remarkable that engine surging during takeoff was not treated in the FAA Approved Flight Manual. Nor did the checklists produced by the manufacturer and SAS contain any by-heart item regarding action in the event of engine surging. The Board further considers that action in the event of engine surging should have been dealt with during the aircraft type training and practised regularly in the simulator.

- With both the aircraft's engines out the pilots were in an extremely difficult position. An emergency landing under such circumstances places great demands upon the pilots, since it is important that the one who is flying the aircraft can devote his undivided attention to flying. In the Board's opinion there is nothing to show otherwise than that the three pilots separately and jointly contributed to the successful emergency landing.

- The damage found to the leading edges of the fan blades is located at the tips of the blades and is of the nature of "soft" indentations without gashes or scratches. This type of damage arises when ice, birds or similar are ingested by the engines. The outer fan blade seal was damaged at the same time by the blades being bent and twisted so that the tips came into contact with the sealing surface and ground away a certain portion of the sealing material.

- The increase in N1 rotation speed changed the relationship between the front and the rear compresser rotation speeds, which reduced the engine surge margin. At the then high power output, there therefore existed the conditions for the aerodynamic disturbances in the fan stage to propagate themselves to the compressors and cause engine surging.

- The first of a number of surges in the right engine was recorded on the QAR and the CVR 25 seconds after liftoff.

- Surging in the left engine started 64 seconds after liftoff.

- The surges subjected the engines to aerodynamic and mechanical stresses that became greater with the increasing engine power. The engine damage indicates that the stg 1 stators were finally broken up by these stresses. The impact damage found on the fan blade trailing edges was caused largely by broken-off stator pieces. The pieces then accompanied the air flow into the front compressors, causing extensive damage to their front stages. Blades and guide vanes in the rear parts of the compressors were damaged by pieces struck loose further forward in the engines.

Source: SHK Statens haverikommission Accident Report, ¶2.1

- It is well known that clear ice can form on the upper surfaces of wings under conditions of high atmospheric humidity or rain in combination with greatly chilled wings. It is also well known that such ice is broken off through movements of the wings on liftoff.

- During the flight from Zurich the fuel had become greatly chilled. On landing there were 2,550 kg of fuel in each wing tank, which represents approx 60% of the tank volume. This volume of fuel was enough to chill the upper surfaces of the wings. The meteorological conditions for the formation of clear ice where almost optimal. The flight technician who inspected the plane during the night noted that clear ice had already formed on the wings. In addition, passengers saw during the de-icing that the indication tufts were not moving and on liftoff that ice was coming off the wings. It is clear from 2.3.2 that the engine damage was initiated by "soft" objects being sucked into the engines.

- Against this background the Board of Accident Investigation finds it beyond all doubt that clear ice loosened from the wings in connection with the aircraft's liftoff, and that the ice was then ingested by the engines.

- There were no detailed instructions in defined nomenclature that described how to check for the presence of clear ice, how the ice should be removed or how the follow-up check and the report to the captain should be effected.

- In the present case it should have been clear to the mechanic that he should check whether there was any clear ice, since rime had been noted on the underside of the wings in the tank area. He did perform this examination by climbing up on a ladder and, with one knee up on the leading edge of the left wing near the fuselage feel the upper side of the wing with one hand. He could not discover any clear ice there and concluded wrongly that there was no clear ice further aft either. There was ice there, however, on an area which he, with this particular means of checking, could not reach.

- To be able to carry out an effective examination it would have been necessary for the mechanic to have gone out onto the wing, which was slippery because of the precipitation.

- Since he could not find any clear ice before the de-icing, the mechanic had no reason, given the instructions in force, to check this again after de-icing had been carried out.

- The risk of ingestion of clear ice by the engines of the aircraft type has been known for many years. As early as 1985 a DC-9-51 suffered serious engine damage for this reason. On the MD-80 series, the risk is greater due to the configuration of the wing tanks and the larger engine air intake area. The manufacturer has therefore over the years taken a number of steps to inform operators of the problem and has distributed numerous service bulletins intended to reduce the risks.

- The problem has thus long been known within SAS. In 1987 the aircraft were equipped with warning triangles with indication tufts to facilitate the discovery of clear ice. The matter has also been covered in internal information over the years. In, among other places, the Winterization Bulletin to all SAS pilots, issued in October 1991, the problem was elucidated once again. It was stated that it is the captain's responsibility to check the presence of snow and ice which might affect the aircraft's performance.

- The (Swedish-language) "Line Maintenance De-icing Instructions, Winter 1991/92" for the Arlanda base contains the following statement about clear-ice control. "Physical hand contact with the wing upper side and tapping with the back of a screwdriver are the only reliable methods of discovering clear ice ... if external conditions give reason to suspect clear ice, the upper sides of both wings must be inspected even if the wing inspected first is free of clear ice."

Source: SHK Statens haverikommission Accident Report, ¶2.4

4

Cause

As pilots we are forced to make many assumptions about risk that have a direct impact on our abilities to operate safely. Our training and experience level can mitigate areas where our assumptions are faulty. These pilots had to rely on the ground crew to correctly de-ice the airplane; but with a little more experience they may have been more suspicious about the likelihood of ice forming after the deicing. They hadn't been trained on how to recognize and then deal with an engine compressor stall. But they did a very good job of finding a soft spot to crash their disabled aircraft and did so well enough to save the lives of everyone on board.

- The accident was caused by SAS' instructions and routines being inadequate to ensure that clear ice was removed from the wings of the aircraft prior to takeoff. Hence the aircraft took off with clear ice on the wings. In connection with liftoff, the clear ice loosened and was ingested by the engines. The ice caused damage to the engine fan stages, which led to engine surges. The surges destroyed the engines.

- Contributory causes were:

- The pilots were not trained to identify and eliminate engine surging.

- ATR - which was unknown within SAS - was activated and increased the engine power without the pilots' knowledge.

Source: SHK Statens haverikommission Accident Report, ¶3.2

References

(Source material)

14 CFR 121, Title 14: Aeronautics and Space, Operating Requirements: Domestic, Flag, and Supplemental Operations, Federal Aviation Administration, Department of Transportation

14 CFR 135, Title 14: Aeronautics and Space, Operating Requirements: Commuter and On Demand Operations and Rules Governing Persons on Board Such Aircraft, Federal Aviation Administration, Department of Transportation

Report C 1993:57, Air Traffic Accident on 27 December 1991 at Gottröra. AB. county, Case L-124/91, SHK Statens haverikommission, Board of Accident Investigation.