"The Rules" are twenty-six ideas I've collected over the years that seemed relevant enough to life in general that I've written each down with a short story to reinforce each in particular. This is Rule Number Twelve.

— James Albright

Updated:

2021-00-00

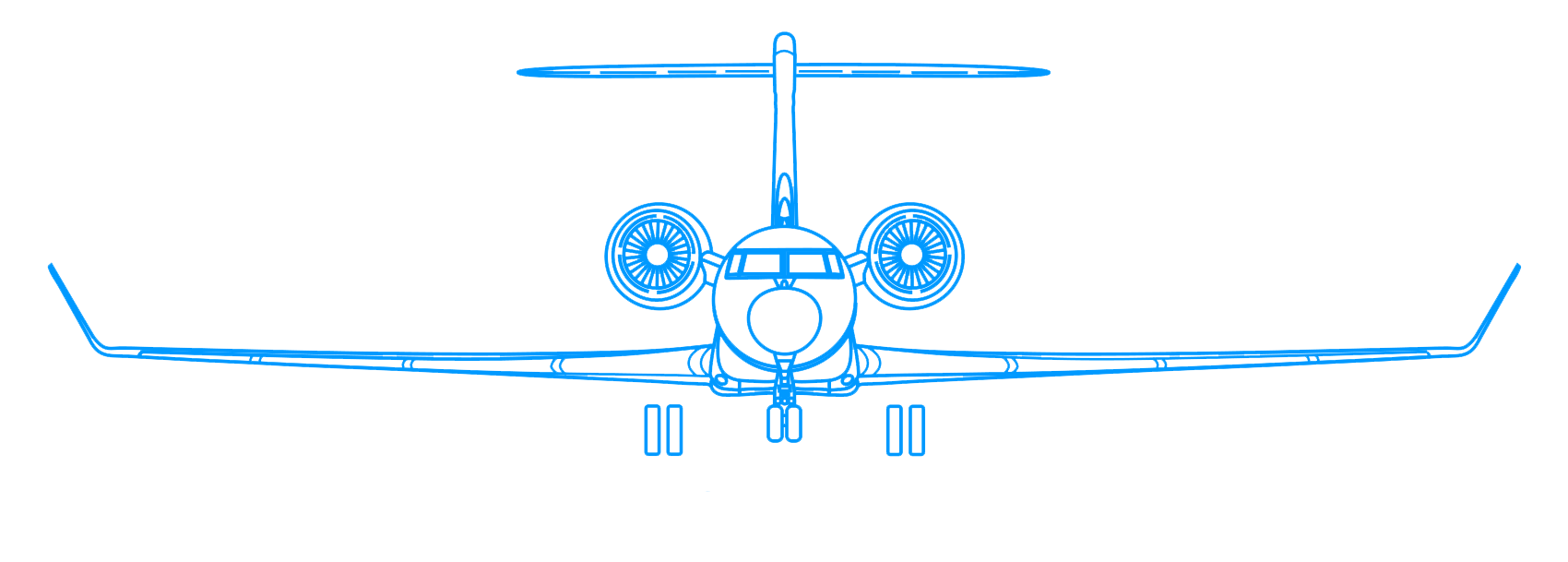

Back in the days when airplanes were not much more than gears, levers, and a few electrons just to keep things lit and maybe view a few analog instruments, the only thing keeping much of the airplane within its limits were the pilots. If you pushed a lever too far, flew the airplane too low, or did any number of things the book told you not to, well bad things happened.

As a bona fide copilot, one who had never sat in the left seat of an airplane requiring two pilots, you learned to keep your mouth shut and eyes open. Sometimes you need to speak up . . .

A man's got to know his limitations

1980

I showed up at Loring Air Force Base in Maine with, I knew, high marks from tanker copilot school. The airplane was massive compared to what I had been flying: the KC-135A maxed out at 297,000 lbs. where the T-38 tipped the scales at 12,500 lbs. Despite that, it was an easy airplane to fly and school was easy.

“You Lieutenant Albright?” the commander’s secretary asked.

“Yes ma’am,” I said.

“Don’t call me ma’am, I’m a civilian,” she said humorlessly, “I work for a living.”

I marched into the commander’s office, saluted, and announced my presence.

“Welcome, lieutenant,” the colonel said, “we’ve been looking forward to your arrival. We never had a top grad copilot before.”

“Top grad?” I asked. I didn’t know that.

“Yeah,” he said, “and have we got a challenge for you.”

Lieutenant Colonel Francis Gilliam was the commander of the 407th Air Refueling Squadron and was in charge of eighteen airplanes and nearly a hundred crewmembers, including me. He proceeded to tell me everything there was to know that was bad about Captain Rick Stiles, the leader of crew S-105. He painted a picture of a pilot who could barely keep the airplane right-side-up, much less lead a crew. I wondered why he was spilling his guts to me, his newest and youngest copilot.

“And that, lieutenant, is why we are assigning you to crew S-105.” I stared blankly, thinking it all a horrible joke. I guess the commander needed more from me. “You keep Rick out of trouble for a year, and we’ll make sure we take care of you James. Nuclear alert is serious business. You can do it, I know you can.”

That was June of 1980 and after two months I came to the conclusion Captain Stiles was not so bad after all. He didn’t know the airplane like he should have and his instrument technique was sloppy. But he was good to the crew and wasn’t shy about giving me stick time. I sensed we were not one of the trusted crews in the squadron – we never got the plum missions, only the routine ones that didn’t need a really good crew – but you have to bloom where you are planted and I was comfortable on S-105. And with those low expectations I was overjoyed in September when we were selected to fly to Diego Garcia by way of California, Hawaii, and Guam. My first trip outside the United States would be three quarters the way around the globe. It was going to be great.

But perhaps, before we continue, I must get into the mechanics of the princely duty of KC-135 Copilot. There is a long tradition of Air Force copilots, subject of derision of crew and non-crew alike, made only worse when said copilot is a second lieutenant. A butter bar. Hell, there is great poetry dedicated to the subject:

The Copilot

I am the copilot, and I sit on the right,

It's up to me to be quick and bright,

I never talk back for I have no regrets,

But I have to remember what the Captain forgets.

I make out the flight plan and study the weather,

Pull up the gear and stand by to feather,

Make out the mail forms and do the reporting,

And fly the old crate while the Captain is courting.

I take the readings, adjust the power,

Put on the heaters when we're in a shower,

Tell him where we are on the darkest of night,

And do all the book work without any light.

I call for my captain and buy him cokes,

I always laugh at his corny jokes,

And once in a while when his landings are rusty,

I always come thru with "by gosh it's gusty!"

All in all, I'm a general stooge,

As I sit on the right of the man I call "Scrooge",

I guess you think that it’s past understanding,

But maybe someday he will give me a landing.

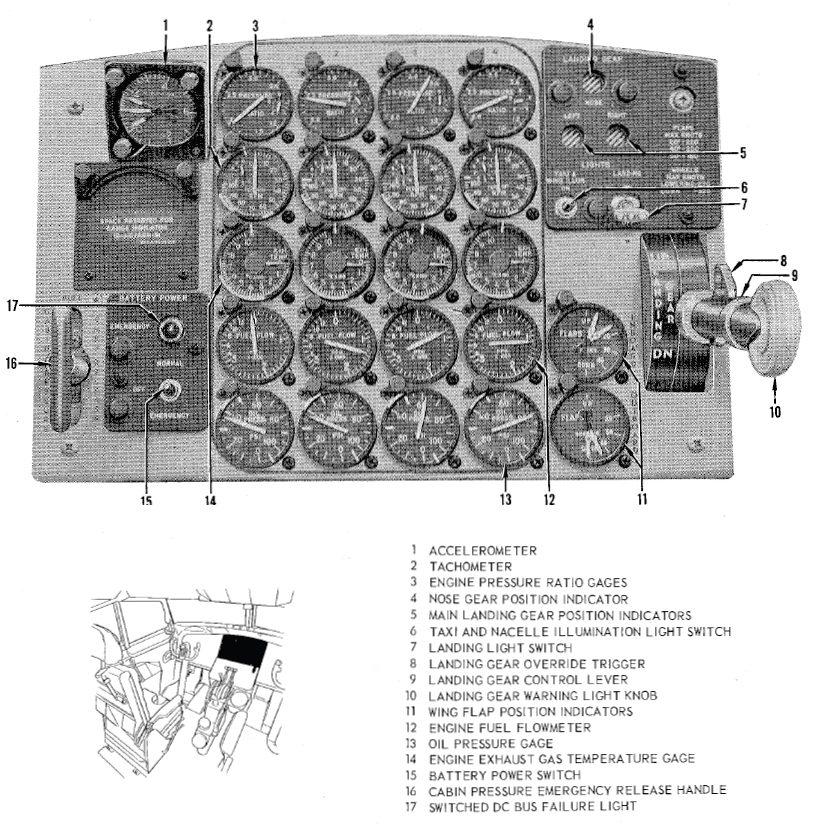

In the KC-135A tanker, the copilot computes the takeoff data – the numbers that tell us what EPR to used when setting the engines at takeoff power and what speeds to use when deciding to continue a takeoff or reject a landing when one of four engines quit – does the cockpit preflight, helps set the engines for takeoff, raises the landing gear and flaps, and does whatever the captain needs doing when it needs to be done.

Now, about the setting takeoff power part. The captain pushes all four engines to “about” takeoff power, then the copilot takes over and fine tunes them to the exact number. The engine pressure ratio measures the air pressure coming out of the engine and divides that by the pressure of the air going into the engine. On our mighty KC-135A, that number is usually 1.83. Sitting below the four EPR gauges are a bunch of other gauges that tell us when the engine is turning too fast, is using too much fuel, or is just too hot. The copilot has to keep all those dials out of the red. Which is where I found myself on during my first takeoff with Captain Stiles.

“Woah,” I said with my left hand full of throttles, “over temp on one and three.” I pulled them back and Captain Stiles happily nodded and continued the takeoff.

“Should we write the engines up, sir?” I asked after the flight.

No, the good captain assured me, these engines were designed to take a little abuse and engineers always included a fifty percent fudge factor on all limits. We didn’t need to concern ourselves with alerting the maintenance folks that the engines were pushed a few degrees beyond their design limits.

Of course I have an engineering degree and know the fifty percent fudge factor is hogwash. But I am new to the tanker and the captain has been doing this for twelve years. I resolve to listen and learn.

After two months it became routine: Captain Stiles pushed all four throttles the their forward stops and I raced to pull them back before any of the gauges blinked red. He was happy and the engines hadn’t complained. Yet.

We had eighteen tankers up at Loring and we, Crew S-105, were assigned to fly any of them on a random basis. We rarely saw the same airplane twice in a month. In fact, in my three or four months at Loring, I had yet to repeat an aircraft. Until the deployment. We were assigned KC-135A 56-3637, an airplane that came out of Boeing Field, Washington the same year I appeared in Tokyo, Japan. I would, for the first time in my two years as an Air Force pilot, fly the same airplane on every sortie for a month.

Day One. We flew from Loring, Maine to Riverside, California on 2 Sep 1980. As per usual, Captain Stiles pushed all four throttles to the forward stop and I pulled them back as quickly as I could. The number three engine EGT – engine gas temperature – flashed red and the needle made its way half way through the red zone before I arrested its progress. After 6.7 hours we were in Riverside, California and the next day would be my first ocean crossing.

“Number three got really hot, sir.” I thought but did not say that I was concerned about the engine’s health for the trip to Hawaii.

“No problem,” Captain Stiles said, “they do that all the time. Besides, the EPR was just fine.”

Curious, I thought. The EPR gauge didn’t have a red zone. I looked it up in the book and it was true. There were no EPR limits.

Time for another side bar, a parallel story about creep. Engine creep. Creep is actually an engineering term to describe the slow but inevitable movement of metals in reaction to high temperatures over time. I knew, from Purdue, that even the strongest alloys were subject to creep when subjected to very high temperatures. The KC-135A engine, the Pratt & Whitney J57-P43W, had 16 stages of compressors and 3 stages of turbines where the metal blades were rated to 650°C degrees. On 2 Sep 1980, I saw an engine reach 660°C.

Day Two. The takeoff out of March Air Force Base, Riverside, California, was just like the day prior, except this time number three reached 680°C. I decided it made it higher because of the higher pressure altitude of the airport, not my slowing reflexes. Despite all that, 6.2 hours later we were in Hawaii. Home again.

Day Three. The very next day we got to depart using the reef runway at Honolulu, International. I always wanted to do that. Number three only made it to 670°C, still 20 degrees higher than its design limit. But still, I was getting better. (Plus we were at sea level.) After 8.1 hours, we were in Guam.

Day Seven. The good folks at the Guam tanker task force gave us four days off before we flew our first mission. That was on somebody else’s airplane, 63-8007 – the newest tanker I had ever flown. Its engines seemed to like Captain Stiles better and there were no red lights on takeoff.

Day Nine. We were back to our airplane, 56-3637, the airplane that was as old as me. It looked much worse for wear. The skin was wrinkled from nose to tail, the paint was tired, and the cockpit looked old and tired too. But it was our airplane and I was happy to see her.

The flight for the day was to be my first maximum weight takeoff. Captain Stiles decided it was time for me to check that off my list of things to do. We would load her up to 297,000 lbs. of gross weight. He would taxi her to the end of the runway and we would both stand on the brake pedals. He would push all four throttles to their limits, I would dive at them to bring them back into the green. He would direct me to start the water injection system that would raise us from around 9,000 pounds of thrust per engine to just over 12,500 pounds of thrust. He would count us down --- “three, two, one” – and we would release the brakes. And then we would thunder down the runway. At 80 knots he would say “your aircraft,” and I would answer “my aircraft.” At 150 knots or so, I would slowly pull back on the yoke and we would lumber into the sky. It was going to be great.

Theory versus reality.

We were the last airplane in a twelve-ship formation. The first six airplanes were B-52 bombers on their way to the Indian Ocean. The next six were KC-135 tankers following closely behind. The interval between bombers was 12 seconds, between the last bomber and the first tanker would be 30 seconds, and 12 seconds again for each following tanker. At the runway’s midpoint was a fleet of base cars, the wing commander I knew was in attendance. I guess this was a big inspection for the base. At last I could hear the wing king’s voice on the command post frequency. “This is Alpha, you are cleared to launch. Make us proud.” An odd request, I thought.

As each airplane crossed the runway threshold and pushed forward, their engines and water injection filled the sky with black smoke. By the time we got there, it was all Captain Stiles could do just to keep the airplane on the runway. He jammed all four throttles to their forward stops while I was mesmerized by all the noise, smoke, and vibration. I grabbed at the throttles, all four sporting red temperature lights, and brought each into the correct zone. At 80 knots I heard, “your aircraft.”

I tightened my grip on the yoke and placed my feet on the rudder pedals. The ailerons and elevators were buffeting a bit from the wake turbulence and jet exhaust from the eleven airplanes in front of us, but that was to be expected. The acceleration wasn’t breathtaking but we were gaining speed.

I had seen a maximum weight takeoff twice before, both times in the cold Maine climate where the engines had denser air to turn F into m, a, and the wings had a fighting chance to turn the coefficient of lift into actual lift. Today, in Guam, it was nearly 100 degrees and the airplane consumed half the runway and we were nowhere near decision speed.

Once we got to decision speed, we no longer could abort the takeoff and were committed. While the rest of the world and the rest of the United States Air Force called decision speed “vee one,” vee being short for velocity and one being the first of several key velocities. In the Strategic Air Command, it was S-1, S for speed. After S-1, we could no longer abort.

“S-1,” I heard Captain Stiles say just as I saw a bright flash of light pass the aircraft out of my right window and then heard the explosion. The airplane pulled, gently at first, but then more noticeably to the right. I corrected with left rudder. The pilot stayed quiet as I concentrated on keeping the airplane straight and waited for rotation speed. It wasn’t coming.

With about a thousand feet of runway to go, Captain Stiles announced, “Rotate.” I glanced at the airspeed indicator and saw we still needed another twenty knots. Back to looking outside, we had a thousand feet of runway left. No choice, I rotated.

They say you need to rotate 3 to 4 degrees per second up to the target attitude of 8-1/2 degrees. They also say that if you rotate too fast and speed is critical, you risk stalling the wing and it will never end up flying. I pulled back ever so gently. We made it to 8-1/2 degrees and the airplane reluctantly left the grip of the earth. But it didn’t do much after that. For seconds, long agonizing seconds, the airplane seemed to mush along at 600 feet, the elevation of the runway.

“Clear to dump,” I heard on the radio and from the corner of my eye I saw Captain Stiles flipping switches on the fuel panel to get rid of all that gas that was meant for a B-52 but now would find itself as a thin membrane atop the Pacific Ocean. As the thousands of pounds shot out the ass end of the airplane, the nose end started to respond to my coaxing. At last we were gaining altitude. With another few minutes I was able to dip a wing below the horizon without fear of having the rest of the airplane follow it. In another thirty minutes we were on the ground.

As we climbed down the crew entry ladder we each raced over to the number three engine only to be stopped by the fire crew. It was still smoldering and the gray cowling was black from soot and flames. Every colonel on base came by to shake Captain Stiles’ hand for ably dealing with a heavy weight engine failure. Each time he pointed to me. Half the colonels then reached to shake my hand. The other half looked at the butter bars on my shoulders and walked away.

When we got back to Loring there was a commendation waiting for each of us on the crew. Captain Stiles was as happy as I had ever seen him. Me? Not so much. I knew the cause of the engine failure. It was a secret I kept with me for many years.

The Air Force later got wiser on the subject of engine blade creep and added a section of most flight manuals about the cumulative nature of over-temping compressor and turbine blades. Later airplanes would have automatic systems to record such over-temps and still later would be computer controlled so such engine abuse was impossible.

It was my second engine failure at decision speed during takeoff. It would not be my last.