Most of my experience is with single point refueling and this is certainly not a complete description of the fueling process.

— James Albright

Updated:

2018-07-25

Most of what follows is from the Standard for Aircraft Fuel Servicing. You can view this document for yourself at the NFPA Website, but the document will cost you $$ so I've copied the good bits here.

3 — Engine operation during refueling

6 — Aircraft occupancy during refueling

Note: This is all written from the perspective of a pilot trying to fuel his or her aircraft. If you are the person responsible for the fuel truck, I cannot recommend strongly enough picking up a copy of the Standard for Aircraft Fuel Servicing. You can register on the NFPA Website for free and read the document at no cost.

1

Bonding requirements

Truck to Aircraft

We used to speak of "grounding" in that we were required to connect the aircraft electrically to the ground and the fuel truck to the ground. It was considered the safe way to do things until somebody figured there could still be a difference in electrical potential between the airplane and truck. In other words, you could still get a spark between the two. So now we bond the aircraft to the truck. There is no longer a need to ground either.

By the way, I will use "ground" and "bond" interchangeably. Most aircraft flight manuals still say "ground" when they should say "bond."

Electrostatic Hazards and Bonding.

- A provision for bonding shall be incorporated in the design of fuel servicing vehicles or carts and systems to prevent differences in electrostatic potential in accordance with Section 5.4.

- The maximum resistance between the bonding cable clip and the fueling system framework shall not exceed 25 ohms.

- Bonding cables shall be constructed of conductive, durable, and flexible material.

- Bonding connections shall be electrically and mechanically firm. Jacks, plugs, clamps, and connecting points shall be clean, unpainted metal to provide a positive electrical connection.

Source: NFPA 407, ¶4.1.2

Bonding

- Prior to making any fueling connection to the aircraft, the fueling equipment shall be bonded to the aircraft by use of a cable, thus providing a conductive path to equalize the potential between the fueling equipment and the aircraft. The bond shall be maintained until the fueling connections have been removed, thus allowing separated charges that could be generated during the fueling operation to reunite. Grounding during aircraft fueling shall not be permitted.

- In addition to [these requirements], where fueling over wing, the nozzle shall be bonded with a nozzle bond cable having a clip or plug to a metallic component of the aircraft that is metallically connected to the tank filler port. The bond connection shall be made before the filler cap is removed. If no plug receptacle or means for attaching a clip is available, the operator shall touch the filler cap with the nozzle spout before removing the cap in order to equalize the potential between the nozzle and the filler port. The spout shall be kept in contact with the filler port neck until the fueling is completed.

- Bonding and fueling connections shall be disconnected in the reverse order of connection.

Source: NFPA 407, ¶5.4

How Not to Ground / Bond

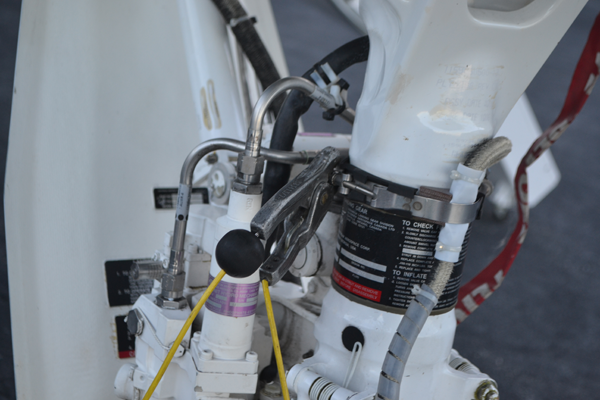

This seems to be the most popular place to bond the aircraft. The problem is there is a layer of lubricating grease between that bolt and the airplane. I put an ohm meter between this point and the aircraft and got a reading of 50,000 ohms; meaning the connection was extremely poor. (The standard is 25 ohms or less.)

How Not to Ground / Bond, Part Deux

There is clearly a rubber grommet surrounding that strap. I've seen this twice and each time the fuel truck operator seemed embarrassed when I corrected it. I put an ohm meter between this point and the aircraft and got a reading of infinity; meaning there is no connection at all, you might as well leave the cable on the truck.

How Not to Ground / Bond, Third Time is a Charm?

The fuel truck operator didn't understand what was wrong with attaching his ground wire in the engine outlet cover. Be careful out there.

How to Bond

We have two proper ground points on our aircraft, this one by the nose and another on the right wing. We keep a spare plug in case the truck only has the clip.

How to be prepared

If your airplane has the "ground jacks" but your fuel truck doesn't, you can be prepared. Your mechanic probably has these parts tucked in the back of his tool box, a 1/4" plug with metal handle and a "Remove Before Flight" flag. Keep one of these in your door compartment and you will always be ready for the truck that only has a grounding plug with an alligator clip.

2

Radar restrictions

- Surveillance radar equipment in aircraft shall not be operated within 90 m (300 ft) of any fueling, servicing, or other operation in which flammable liquids, vapors, or mist could be present.

- Weather-mapping radar equipment in aircraft shall not be operated while the aircraft in which it is mounted is undergoing fuel servicing.

Source: NFPA 407, ¶4.1.4.1

3

Engine operation during refueling

Operation of Aircraft Engines and Heaters.]

- Fuel servicing shall not be performed on a fixed wing aircraft while an on board engine is operating.

- Combustion heaters on aircraft (e.g., wing and tail surface heaters, integral cabin heaters) shall not be operated during fueling operations.

Exception: In an emergency resulting from the failure of an on board auxiliary power unit on a jet aircraft and in the absence of suitable ground support equipment, a jet engine mounted a the rear of the aircraft or on the wing on the side opposite the fueling point shall be permitted to be operated during fueling to provide power, provided that the operation follows written procedures approved by the authority having jurisdiction.

Source: NFPA 407, ¶5.5

4

Fuel servicing locations

Aircraft Fuel Servicing Locations.

- Aircraft fuel servicing shall be performed outdoors. Aircraft fuel servicing incidental to aircraft fuel system maintenance operations shall comply with the requirements of NFPA 410.

- Aircraft being fueled shall be positioned so that aircraft fuel system vents or fuel tank openings are not closer than 7.6 m (25 ft) to any terminal building, hangar, service building, or enclosed passenger concourse other than a loading walkway. Aircraft being fueled shall not be positioned so that the vent or tank openings are within 15 m (50 ft) of any combustion and ventilating air-intake to any boiler, heater, or incinerator room.

Source: NFPA 407, ¶5.10

NFPA 410 is available at www.nfpa.org.

5

Fuel testing

We tend to rely on the FBO for fuel quality testing but sometimes you aren't familiar with the FBO, sometimes the fuel truck causes you to wonder if those engines will keep running once full thrust is added on takeoff. In either case, you may want to sump and test the fuel in your tanks. Unfortunately there is little written about this in most pilot manuals. What follows comes mostly from Fuel Handling Jet Quality and Test Procedure, published by PetroValue Aviation, a Canadian fuel wholesaler.

White Bucket Test

- The white bucket is a simple but reliable test for detection of significant amounts of water and particulates. Water occurs in different forms in the fuel;

- Dissolved in the fuel, normally this water can not be removed from the fuel.

- Suspended or entrained in the fuel. Entrained water can be detected with the naked eyes. The fine droplets of water in fuel reflect light and in high concentration give the fuel a cloudy or hazy appearance.

- Water in high quantity into fuel may be caused by leakage into storage tanks, delivery of water laden fuel, condensation or the coalescence and subsequent settling of entrained water.

- Particulate or dirt is normally found in fuel in the form of rust, scale, lint, dust, particles from gaskets and hoses which have been released from the side of the tanks, piping and transportation vehicles.

- A bucket, white porcelain lined or stainless steel of a capacity of seven litters (7 L) and with a bonding cable (a separate cable if not equipped, must be provided). A shiny coin with well-defined feature is an additional tool.

- Bucket must be clean and dry.

- A static bonding cable must be connected between bucket and the source of sample container, pipe or valve as required.

- Take a sample at system operating pressure (except samples from a storage tank or transport trailer). Fuel in the drain or line should be removed or displaced before taking sample. Valve should be completely open without causing spill.

- Fill bucket at least 15 cm of its depth.

- Place bucket on a level surface and allow it to stand for few minutes to settle sample to ensuring no air bubbles present.

- Visually inspect and observe the fuel sample to determine presence of free water, particulates, unusual colour, haze, floating material and lacy substance layers.

- Swirling of sample will cause dirt or water to collect at the centre of bucket for easier examination.

- Drop a coin with well-defined features into the fuel sample bucket to assist visual detection of haze.

- Evaluation

- Observed colour of jet fuel should be colourless to a light straw. Colour should be similar to previously acceptable test if any.

- A cloudy or haziness condition in appearance of the fuel sample suggests water contamination.

- If sample does not appear cloudy, a drop of food colouring or coffee added to the sample will ensure absence of water when coloured drop settles at the bottom. If it dissolves in the sample the fuel is not pure and contaminated with unacceptable amount of water.

- Slime on the bottom surface of container or lacy substance is an indication of Microbiological Contamination.

Source: Fuel Handling Jet Quality and Test Procedure, ¶1.0

Clear and Bright Test

- Delivered fuel must be clean, bright and not contaminated with free water.

- “Clear” is a visual condition of fuel with the absence of cloud, emulsion, visible particulate matter or entrained water. “Bright” is the quality of fuel refers to the shiny and sparkling appearance of clean and dry fuel.

- The “bright and clear” condition of the fuel is not dependent on the natural colour of the fuel.

- The “Clear and Bright” test is a visual check and conducted to detect water or other solid contaminants in the fuel. An evidence of external contaminants renders the fuel as “not suitable for use” and points to a requirement of further laboratory analysis.

- Glass Jar – a wide mouth glass jar of 7.5 cm (3 in.) in diameter or other similar transparent container. A white paper sheet or light background surface material is a great tool to enhance detection of contaminants.

- Evaluation

- Observed colour of jet fuel should be colourless to a light straw. Colour should be similar to previously acceptable test if any. Observed colour of jet fuel should be colourless to a light straw. Colour should be similar to previously acceptable test if any.

- A cloudy or haziness condition in appearance of the fuel sample suggests water contamination.

- If sample does not appear cloudy, a drop of food colouring or coffee added to the sample will ensure absence of water when coloured drop settles at the bottom. If it dissolves in the sample the fuel is not pure and contaminated with unacceptable amount of water.

- Slime on the bottom surface of the jar or lacy substance at the water surface where it contacts fuel is an indication of Microbiological Contamination.

- Contaminants found in fuel sample would suggest a need to inspect the source of contaminants and could also be attributed to the failure of equipment or procedures.

Source: Fuel Handling Jet Quality and Test Procedure, ¶1.1

Free water contamination in fuel can go undetected using visual test methods. There are number of free water detection kits available for field use such as the Velcon Hydrokit® and the Shell Water Detector®. A water sensitive chemical product is used with the fuel sample which reacts with the suspended water content in the fuel by changing its color.

Other Contaminants

There are several other worrisome contaminants that may escape visual detection. Unfortunately, you are pretty much at the mercy of the fuel provider to do the necessary tests. It is to your advantage to make sure the fueler is busy; there is no better reassurance than knowing airplanes have been successfully flying using the same fuel all day. Here are a few things to worry about and a thought or two about each.

Rust is generally the leading source of particulate contamination. Frequently the sand or dust could also be present. The main source of this kind of contamination is erosion and corrosion of container surfaces, pipes, fittings, pumps cavity erosion and any other source which come in contact with the fuel.

Source: Fuel Handling Jet Quality and Test Procedure, ¶1.3

The best test is force fuel under pressure through a filter membrane with pores as small as 0.8 microns. A collection of rust or sand will discolor the membrane. The FBO should be doing this. I don't think any commercially available portable pilot-operated fuel testing kits have this capability.

Micro-organisms may enter in aviation fuel in many ways such as air, sea or fresh water, soil or by other means. Micro-organism causes significant damage to the fuel system by means of slime formation, sludge and corrosion.

Source: Fuel Handling Jet Quality and Test Procedure, ¶1.4

These micro-organisms feed on the fuel and produced more micro-organisms. Once they've multiplied enough they can be seen in the fuel as a black gelatinous matter. To detect them early, you need a laboratory test. There are commercially available kits but they aren't really suitable for pilot usage on the road.

6

Aircraft occupancy during refueling

If passengers remain on board an aircraft during fuel servicing, at least one qualified person trained in emergency evacuation procedures shall be in the aircraft at or near a door at which there is a passenger loading walkway, integral stairs that lead downward, or a passenger loading stair or stand. A clear area for emergency evacuation of the aircraft shall be maintained at not less than one additional exit. Where fueling operations take place with passengers on board away from the terminal building, and stairways are not provided, such as during inclement weather (diversions), all slides shall be armed and the Aircraft Rescue and Fire Fighting (ARFF) services shall be notified to respond in standby position in the vicinity of the fueling activity with at least one vehicle. Aircraft operators shall establish specific procedures covering emergency evacuation under such conditions for each type of aircraft they operate. All "no smoking" signs shall be displayed in the cabin(s), and the no smoking rule shall be enforced.

Source: NFPA 407, ¶5.11

I'm not sure about the "one additional exit" part of this. I am looking for something in writing that exempts Gulfstreams in particular, business jets in general from this. I know we do this all the time, but I'm not sure how we are authorized. (I've asked the question of the NFPA, no response yet. The search continues. (If you know, please let me know with the "Contact" link.)

For each aircraft type, operators shall determine the areas through with it could be hazardous for boarding or deplaning passengers to pass while the aircraft is being fueled. Controls shall be established so that passengers avoid such areas.

Passengers shall not be permitted to linger about the plane but shall proceed directly between the loading gate and the aircraft.

Source: NFPA 407, ¶5.11

References

(Source material)

Fuel Handling Jet Quality and Test Procedure, PetroValue Aviation, 2008-2

National Fire Protection Association www.nfpa.org

Standard for Aircraft Fuel Servicing, 2012 Edition, National Fire Protection Association, NFPA 407, NFPA, 1 Batterymarch Park, Quincy, MA 02169-7471