In a previous life flying a Boeing 707 we would occasionally land heavy and end up with a few brakes on fire. We would evacuate the aircraft and watch helplessly as the fire department tried to minimize the damage by spraying foam on the wheels. Every now and then a wheel would simply explode.

— James Albright

Updated:

2014-04-25

Those days are over, most fire departments will not foam your wheels these days. Fortunately, most aircraft brakes are designed better than what we had back then. See: Carbon-Carbon Brakes.

1

Aircraft design

- Design landing stop. The design landing stop is an operational landing stop at maximum landing weight. The design landing stop brake kinetic energy absorption requirement of each wheel, brake, and tire assembly must be determined. It must be substantiated by dynamometer testing that the wheel, brake and tire assembly is capable of absorbing not less than this level of kinetic energy throughout the defined wear range of the brake. The energy absorption rate derived from the airplane manufacturer's braking requirements must be achieved. The mean deceleration must not be less than 10 fps2.

- Maximum kinetic energy accelerate-stop. The maximum kinetic energy accelerate-stop is a rejected takeoff for the most critical combination of airplane takeoff weight and speed. The accelerate-stop brake kinetic energy absorption requirement of each wheel, brake, and tire assembly must be determined. It must be substantiated by dynamometer testing that the wheel, brake, and tire assembly is capable of absorbing not less than this level of kinetic energy throughout the defined wear range of the brake. The energy absorption rate derived from the airplane manufacturer's braking requirements must be achieved. The mean deceleration must not be less than 6 fps2.

- Most severe landing stop. The most severe landing stop is a stop at the most critical combination of airplane landing weight and speed. The most severe landing stop brake kinetic energy absorption requirement of each wheel, brake, and tire assembly must be determined. It must be substantiated by dynamometer testing that, at the declared fully worn limit(s) of the brake heat sink, the wheel, brake and tire assembly is capable of absorbing not less than this level of kinetic energy. The most severe landing stop need not be considered for extremely improbable failure conditions or if the maximum kinetic energy accelerate-stop energy is more severe.

Source: 14 CFR 25, §25.735(f), Brakes and braking systems, Kinetic energy capacity

Brake condition after high kinetic energy dynamometer stop(s). Following the high kinetic energy stop demonstration(s) required by paragraph (f) of this section, with the parking brake promptly and fully applied for at least 3 minutes, it must be demonstrated that for at least 5 minutes from application of the parking brake, no condition occurs (or has occurred during the stop), including fire associated with the tire or wheel and brake assembly, that could prejudice the safe and complete evacuation of the airplane.

Source: 14 CFR 25, §25.735(g)

Overtemperature burst prevention. Means must be provided in each braked wheel to prevent a wheel failure, a tire burst, or both, that may result from elevated brake temperatures.

Source: 14 CFR 14 CFR 25, §25.735(j)

The aircraft is designed to give you five minutes to stop and evacuate after a maximum effort application of the wheel brakes. The wheels are designed to deflate the tires before they are subject to an overpressure explosion.

There have been several cases of Gulfstream aircraft tires catching fire following hot brakes and fuse plugs melting. Fires have included the brakes and wheel wells. None of the most recent events involved takeoff aborts or landings, all involved taxi tests.

2

Prevention

Proper Brake Operation

Brake techniques seldom receive the attention they deserve, but there is help:

Brake Cooling

Recommend:

- Light pedal pressure

- Prolongs stop

- Absorbs same energy

- Results in same peak temperatures

- Brakes cool much faster when not set

- Cool brakes while pointing into the wind

- Crosswind doesn’t reach all brakes equally

- Tailwind blows warm exhaust over brakes

- 15 minutes airborne will cool any overheat condition

- Gear extended at VLE

Source: Gulfstream Brakes 101

Brake Washing

Washing main landing gear wheels using a high-volume high-pressure water source such as a garden hose can potentially saturate the porous carbon brake material. Water saturated brakes may require higher than normal brake pressures to achieve normal aircraft braking. This condition is commonly experienced during the first braking application after landing. Normal braking will return for subsequent braking applications after sufficient brake temperature rise evaporates water out of the carbon brake material. Lightly applying brakes prior to take-off will reduce the potential for this condition to occur on the next brake application. When cleaning the main landing gear wheels, Gulfstream recommends hand-wiping only and avoid spraying water or soap solution directly onto the wheels and brake friction surfaces.

Source: Gulfstream G450-MOL-06-0024

Washing carbon brakes with water (maximum 50 psi) should not cause any problems if a couple of precautions are taken:

- Keep the water hose moving. Do not dwell in any one place for more than a few seconds.

- The carbon should be dry before aircraft takeoff. Wet carbon may not provide sufficient friction to make an acceptable Rejected Takeoff Stop.

Note: It is possible to wash off the anti-oxidant coating with excessive water pressure/time.

ABSC says the easiest way to dry out the brake(s) is to make 2 or 3 taxi checks > 40 mph, then let the aircraft sit for several hours. (See Caution below.) These taxi stops should generate enough heat (300+°F) to drive water out of the carbon.

Caution: Gulfstream Flight Ops recommends that any attempt to dry the brakes after washing by performing high-speed taxi stops should be approached with caution. Repeated taxi stops can lead to significant heat build-up in the brakes, which could cause more harm than good. If an operator uses this procedure, he should limit it to ONE 40-knot taxi stop, unless the airplane is equipped with BTMS. With BTMS, however, the operator should be aware that indicated temperature is slow to rise on ABS carbon equipped airplanes.

Also, to preclude frozen brakes in the winter, any brake washing should be followed by a significant drying period prior to exposing the brakes to freezing temperatures. The brakes may not freeze for takeoff but may be frozen upon landing.

Source: Gulfstream Breakfast Minutes, June 29, 2007, pg. 4

3

Example: G450 brake energy

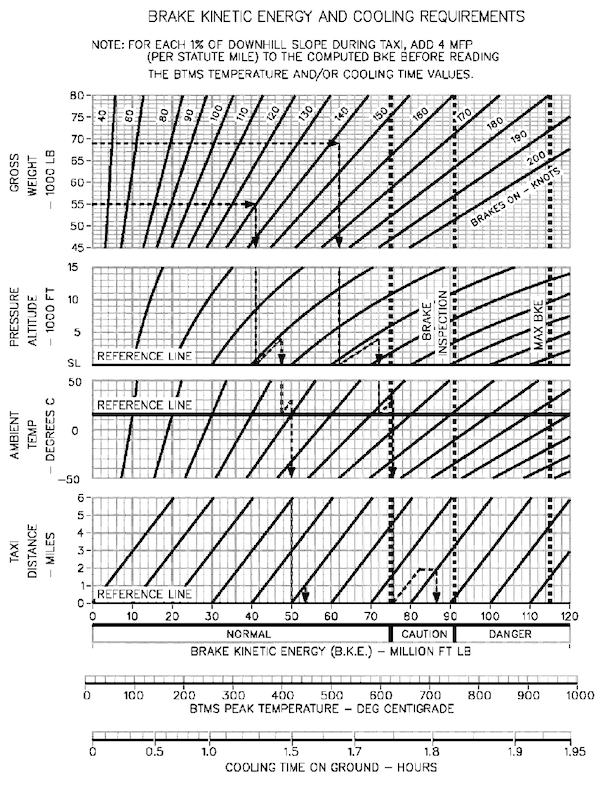

Brake kinetic energy and cooling requirements, from G450 Airplane Flight Manual, Appendix C, page C-10.

FUSEPLUG INTEGRITY ZONES. Each main wheel is equipped with fusible plugs, (subsequently referred to as "fuse plugs"). These fuse plugs are designed to melt to protect the wheel from rupture in the event of excessive heat buildup during braking. Three fuse plug integrity operating zones have been defined to indicate the likelihood of fuse plug release. These fuse plug integrity zones relate to the accumulated BKE levels absorbed during braking. Appropriate actions in each zone are listed below:

NORMAL ZONE: Fuse plug release not likely; BKE less than 75 MFP.

- Delay subsequent activity to provide the cooling time required to restore the required level of brake energy capability.

- Avoid using the parking brake (use chocks) when possible.

- When operating in the normal zone at BKE levels above 60 MFP, care should be taken to avoid uneven braking.

- Idle reverse thrust is recommended to assist taxi stops (reduces brake wear and BKE levels).

CAUTION ZONE: Fuse plug release possible; BKE between 75 - 91 MFP.

- Move the airplane from the runway. One or more of the tires could deflate.

- Use the brakes sparingly to maneuver, using idle reverse thrust to assist taxi stops.

- Do not set the parking brake; chock the nose wheel if required, do not approach the main gear.

- From a safe distance, visually monitor the brakes. Allow the brakes to cool per the BKE Cooling chart cooling times.

- Visually inspect the wheels and brakes after cooling. Check tire pressures per the aircraft maintenance manuals. If fuse plugs have released, remove components for inspection.

DANGER ZONE: Fuse plug release probable; BKE greater than 91 MFP.

- Clear the runway immediately as the fuse plugs will blow 2 to 30 minutes after the last major braking activity. Use idle reverse thrust to assist all maneuvering and taxi stops.

- Evacuate the airplane.

- Do not apply "ansul" dry chemical or quench until fuse plugs have released the tire pressure.

- Do not set the parking brake; chock the nose wheel if required.

- Firemen should not approach the airplane for thirty (30) minutes and pilots and maintenance crews should not approach the airplane for two (2) hours or until all of the fuse plugs have blown.

- When artificial cooling is not used, allow adequate cooling time per the BKE Cooling chart for safe removal of the wheel/brakes.

- A tear down inspection is required after cooling. Remove the wheels, brakes and tires, and inspect per aircraft maintenance manuals.

Source: G450 Airplane Flight Manual, Appendix C

The brakes synoptic page shows the temperature of each brake instantaneous, as well as the peak temperature achieved.

If you are flying a series of short hops you should keep an eye on brake temperatures. A normal brake application will add about 200°C to your brakes. The temperature continues to increase after the brake application. The AFM says peak temperature occurs about 5 minutes after brake application but I've seen the temperature continue to rise for as much as 30 minutes. (You can help things out by parking parallel to the wind, chocking the wheels and releasing the brakes.) An abort at V1 could take 40 million foot-pounds or more so, as a rule of thumb, If any brakes is over 200°C, I'll get into this chart prior to subsequent takeoffs. If, after takeoff, the temperature is higher than 300°C, I'll leave the gear down to cool the brakes until they are below 200°C.

4

Dealing with a brake fire

There isn't much out there on the subject, here is what I have found. . .

¶12.2.3 The heating of aircraft wheels and tires presents a potential explosion hazard, greatly increased when fire is present. In order not to endanger the members of the airport rescue and fire fighting service needlessly, it is important to distinguish between hot brakes and brake fires. Hot brakes will normally cool by themselves without the use of an extinguishing agent. Most aircraft operating manuals for propeller driven aircraft recommend that flight crew members keep the propeller forward of the fire turning fast enough to provide an ample cooling airflow. Most wheels of jet aircraft have fusible plugs which will melt at about 177°C and deflate the tire before dangerous pressures are reached. When responding to a wheel fire, airport rescue and fire fighting members should approach the wheels with extreme caution in a fore or aft direction, never from the side in line with the axle. Since the heat is transferred to the wheel from the brake it is essential that the extinguishing agent be applied to this area. If further cooling is desired after extinguishment of the fire, the agent should be directed at the brake area only.

¶12.2.4 Too rapid cooling of a hot wheel, especially if localized, may cause explosive failure of the wheel. Solid streams of water should not be used except as a last resort. Water fog can be used but intermittent application of short bursts of 5 to 10 seconds every 30 seconds is recommended. Dry chemical has limited cooling capacity but is an effective extinguishing agent. Once the tires are deflated, any extinguishing agent may be safely used as there is no further danger of explosion.

Source: ICAO DOC 9137-AN/898, Part 1

- Hot Brakes

- Normal cooling: Move aircraft to a suitable location and allow brakes to cool on their own.

- Water mist: Can be deployed from turret or handline.

- Fans: Placing fans may place firefighters very close to the hazard zone.

- WHEEL FIRE

- Apply large amounts of water initially with turrets. Transition to handline application to continue and maintain a cooling effect.

- Wheels are equipped with fusible plugs designed to melt and deflate the tire when the temperature is excessive.

Source: Boeing 747 ARFFF Information

It appears the best response to hot brakes is to face the airplane into the wind, chock the nose gear, keep the parking brake off, and allow the brakes to cool with time. If the brakes get hot enough, the fusible plugs in the wheels should deflate the tires removing the most likely source of explosions. If the brakes and wheels do catch fire, the sources seem to agree on the application of water fog, though Boeing advocates "large amounts of water initially with turrets.

References

(Source material)

14 CFR 25, Title 14: Aeronautics and Space, Airworthiness Standards: Transport Category Airplanes, Federal Aviation Administration, Department of Transportation

Gulfstream G450 Maintenance Operations Letter 06-0024, Landing Gear (ATA 32) Brake and Wheel Washing Guidelines, G450-MOL-06-0024, July 11, 2006

Gulfstream G450 Airplane Flight Manual, Revision 36, December 5, 2013

Gulfstream Breakfast Minutes, GIIB/III/IV ABSC Recommendation for Water Washing of Carbon Brakes, June 29, 2007

ICAO Doc 9137 - Airport Services Manual - Part 1 - Rescue and Fire Fighting, International Civil Aviation Organization, Third Edition, 1990

Salamankas, John, Brakes 101.

Please note: Gulfstream Aerospace Corporation has no affiliation or connection whatsoever with this website, and Gulfstream does not review, endorse, or approve any of the content included on the site. As a result, Gulfstream is not responsible or liable for your use of any materials or information obtained from this site.